Marine Fuel CellsQuiet, clean on-board power generation.(or how to avoid spoiling the perfect anchorage) Marine Fuel Cells You've been sailing all day and you arrive in lovely bay with only a few other boats. You drop the anchor, switch on the anchor light and settle down for a well deserved drink when you hear the battery alarm go off. The wind has dropped and the sun is setting so your wind generator and solar panel are useless. Your only option now is to run your engine for a few hours, ruining the relaxing atmosphere and disturbing your neighbours. Sound familiar? Fuel cells offer the perfect solution to the ever growing need for on-board power. Unlike solar and wind they run throughout the day and unlike your engine, they're near silent. Which Marine Fuel Cell? Our most popular marine fuel cell is the EFOY from SFC. They're small and lightweight and come in ranges from 40W to 105W. Don't let the small output power put you off though. When sizing a fuel cell we always work out your daily usage. On a 30-40 foot yacht this can be about 1kW. The EFOY Comfort 140 (65W) will produce 1.7kW each day. Therefore in conjunction with your batteries you will always have enough power. To help you work out your daily usage, and to select a marine fuel cell for your boat we've put together a simple Marine Fuel Cell Power Calculator. | |||||||

| |||||||

| |||||||

|

воскресенье, 18 сентября 2011 г.

Marine EFOR Fuel Cell

Ross Barlow - part 1

University of Birmingham Researchers Test Hydrogen Fuel Cell Powered Canal Boat

Published on September 3, 2011 at 8:12 AM

By Cameron Chai

The university removed the drive system, fuel tank and diesel motor from an old barge, and replaced them with a battery pack, a fuel cell having a hydrogen storage system, and an efficient electric motor. The converted "Ross Barlow" was launched on Britain's canal system in September 2007. In 2010, the barge made a 105 km, four day journey negotiating around 58 locks. The barge and its travelers consumed 106 kWh of electric energy during the voyage. The hydrogen fuel cell provided 25% of the energy; the batteries provided 71%, while a solar panel supplied 4%. An accompanying boat consumed around 50 L of diesel, which leads to CO2 emissions of around 133 kg. The barge did not produce any CO2.

The university removed the drive system, fuel tank and diesel motor from an old barge, and replaced them with a battery pack, a fuel cell having a hydrogen storage system, and an efficient electric motor. The converted "Ross Barlow" was launched on Britain's canal system in September 2007. In 2010, the barge made a 105 km, four day journey negotiating around 58 locks. The barge and its travelers consumed 106 kWh of electric energy during the voyage. The hydrogen fuel cell provided 25% of the energy; the batteries provided 71%, while a solar panel supplied 4%. An accompanying boat consumed around 50 L of diesel, which leads to CO2 emissions of around 133 kg. The barge did not produce any CO2.

The "Ross Barlow" was fitted with a 10 kW permanent magnet motor, a 1 kW commercial fuel cell and a 47 kWh buffer battery. The university used low maintenance and cost-effective lead acid batteries that were also easily chargeable. The buffer battery was added as the fuel cell capacity was insufficient to directly power the boat.

The Empa developed hydride storage system can store hydrogen having 50 kWh energy content. Zirconium, titanium, iron, vanadium and manganese alloy in powder form is packed inside steel tubes. The powder stores hydrogen and releases it when heated.

If the "Ross Barlow" had to travel 650 km in a year, then its metal hydride storage system would require refueling once in a month. This would translate to an operating lifetime of over 100 years, which would be more than the barge’s lifetime.

Source: http://www.empa.ch/

The University of Birmingham has been testing a hydrogen powered prototype canal boat for inland waterways for around three years. Empa has designed the hydrogen tank for this boat. While the weight of the propulsion system has little significance on a boat, its lifetime must be equal to the lifetime of the boat.

The converted hydrogen-fuelled barge "Ross Barlow" with the Empa-developed hydride storage tank

The "Ross Barlow" was fitted with a 10 kW permanent magnet motor, a 1 kW commercial fuel cell and a 47 kWh buffer battery. The university used low maintenance and cost-effective lead acid batteries that were also easily chargeable. The buffer battery was added as the fuel cell capacity was insufficient to directly power the boat.

The Empa developed hydride storage system can store hydrogen having 50 kWh energy content. Zirconium, titanium, iron, vanadium and manganese alloy in powder form is packed inside steel tubes. The powder stores hydrogen and releases it when heated.

If the "Ross Barlow" had to travel 650 km in a year, then its metal hydride storage system would require refueling once in a month. This would translate to an operating lifetime of over 100 years, which would be more than the barge’s lifetime.

Source: http://www.empa.ch/

среда, 7 сентября 2011 г.

Система очистки ДВС без химии и разборки

|

|

|  |

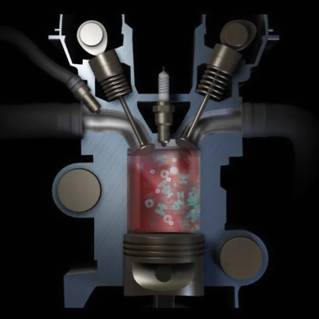

The engine is ready after normal operating temperature has been reached. The carbon cleaning process takes only 40 minutes. Connect the output from the EP-350B to the engine’s intake manifold (vacuum line).

Procedure for performing Engine Carbon Cleaning:

|  |  |

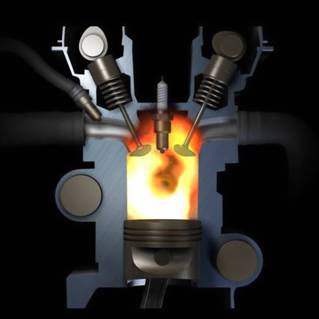

| Connect the EP-350B gas output to the engine’s intake manifold | Oxy-Hydrogen ENRICHED gas enters the engine’s | Complete combustion loosens and eliminates carbon deposits |

Results of Carbon Cleaning with the Epoch EP-350B:

|  |  |

|  |  |

EPOCH EP-350B Carbon deposit removal test report

Date of test procedure: 2009/6/17

Vehicle: 1994MERCEDES BENZ-C180; Displacement: 1.8L; Kilometers: 95,272

Emission Type | Before | After 20min | After 40min | After | Emission reduction rate |

CO(%) | 0.66 | 0.37 | 0.38 | 0.17 | 74% |

HC(ppm) | 414 | 417 | 145 | 99 | 76% |

CO2(%) | 14.1 | 14 | 11.8 | 14.5 | -3% |

O2(%) | 1.34 | 1.53 | 4.16 | 1 | 25% |

NOx(ppm) | 73 | 89 | 71 | 18 | 75% |

| (1)Before | (2)After 20min |

|  |

| (3)After 40min | (4)After completion of procedure |

|  |

Comparison between EPOCH Carbon Cleaning System and traditional methods

EPOCH Carbon Cleaning System | Chemical Drip Method | Chemical Foam Method | |

Medium | oxy-hydrogen gas | chemical additive | chemical additive |

Procedure time | 40mins | 30-40mins | 30-40mins |

Environment Issues | None | air pollution + waste water | waste water |

Advantages/ Disadvantages | Simple to connect; the engine runs at idle | The engine runs at idle while chemical additive drips into the engine | Complicated and repetitive; carbon removal incomplete. |

Cost (Retail) | Carbon Cleaning Process | Chemical Drip Engine oil Engine oil filter | Chemical Foam Engine oil Engine oil filter |

EPOCH EP-350B CARBON CLEANING SYSTEM:

| 1. | Carbon Cleaning using Epoch's Oxy-Hydrogen gas cleans away the carbon build-up efficiently and without mess or harm to the environment. |

| 2. | The results are more low RPM power in a smoother running and more efficient engine. |

| 3. | Carbon reduction results can be seen using a micro-camera, before and after the process. |

| 4. | Different from the traditional carbon reducing methods; no pollution, no harmful gases or chemical additives to harm you, your car or the environment. |

| 5. | Save time and money by using the Epoch EP-350B Carbon Cleaning System; increase your business potential, customer base and profits. |

Conclusion

| After using the EPOCH EP-350B ENGINE CARBON CLEANING SYSTEM, carbon build-up is completely cleaned away, engine efficiency is increased, power and performance are restored, life expectancy is improved and engine emissions are reduced. |

Система для траков и бусов

- Epoch’s newest product line can be easily installed into existing cars, buses and trucks in only a couple of hours;

- Fuel consumption and carbon emissions are reduced;

- Accumulated carbon deposits are cleaned away;

- The service life of the vehicle is extended;

- Pays for itself quickly;

- Additional sizes coming soon;

- Safe: Oxy-Hydrogen gas is produced on demand, without any gas storage. Product liability insurance of 500 million NT dollars

Model Number | EP-C100 | |

DC Voltage Requirement (V) | 24 | |

DC Current (A) | 25 | |

Max. Water Consumption (L/h) | <0.1 | |

Water Reserve (L) | 10 | |

Dimensions WxDxH (cm) | Electrolysis unit | 43x40x38 |

Control unit | 36x12x37 | |

System Gross Weight (kg) | 50 | |

(2) 2009/1 Public Transportation Project-Tpebus/Capital-bus

(3) 2009/4 Public Transportation Project-Korea IC ENERTEC Buses

(4) 2009/5 Public Transportation Project- Kaohsiung Circular line 168 City Buses

(5) 2009/5 Public Transportation Project- KUO-KUANG motor transport company buses

(6) 2009/07 Holland Project

(7) 2009/08 Laredo, Texas Project

(8) 2009/09 Public Transportation Project Agreement signing ceremony- Chinhsi tourist coaches

(9) 2009/09 Thailand Project

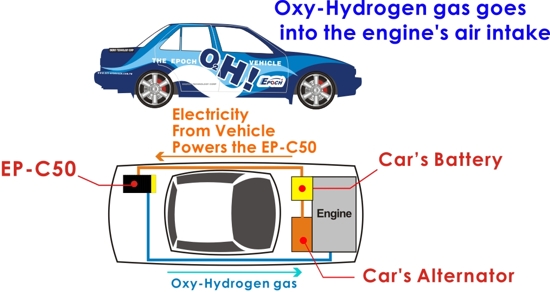

Комплекс для легкового авто

Item No :EP-C50

- Removes Carbon Deposits

- Increases Horsepower & Torque

- Reduces Harmful Emission

- Extends Drivetrain Service Life

This 12 volt system works with both

- Petrol Engines

- Diesel Engines

Technical Principle

|  |

Removes Carbon Deposits

The effect is clearly visible

Before

After

The Choice is Yours:

Increase the Service Life

of Your Car

Reduce Emissions

Improve Engine Efficiency

Increase Horsepower & Torque

Improve your Driving Experience

Easy to install;

Fits in the trunk of any car.

|  |

Подписаться на:

Сообщения (Atom)